From Concept To Manufacture in 9 Months.

The Solution.

An LED array in the footplates acts as a running light when not indicating, creating a premium and clear visual identity, especially when riding at night. When indicating, the array pulses in the direction of intended travel, making it clear to fellow road users your intention.

Designed with Process.

-

Define the Problem.

Electric scooters are seen as unsafe. Many scooters do not have indicators and, when they do, they are positioned on the handlebars. The rider position can block the view of the indicators from behind, hiding the riders intention. When indicators are positioned closer together, on the rear of the scooter, the direction the rider wishes to turn can be unclear, especially in the dark.

Scooters are also seen as cheap toys, rather than premium microbility. For wider adoption of electric scooters to occur, this has to change.

-

Evaluate Solutions.

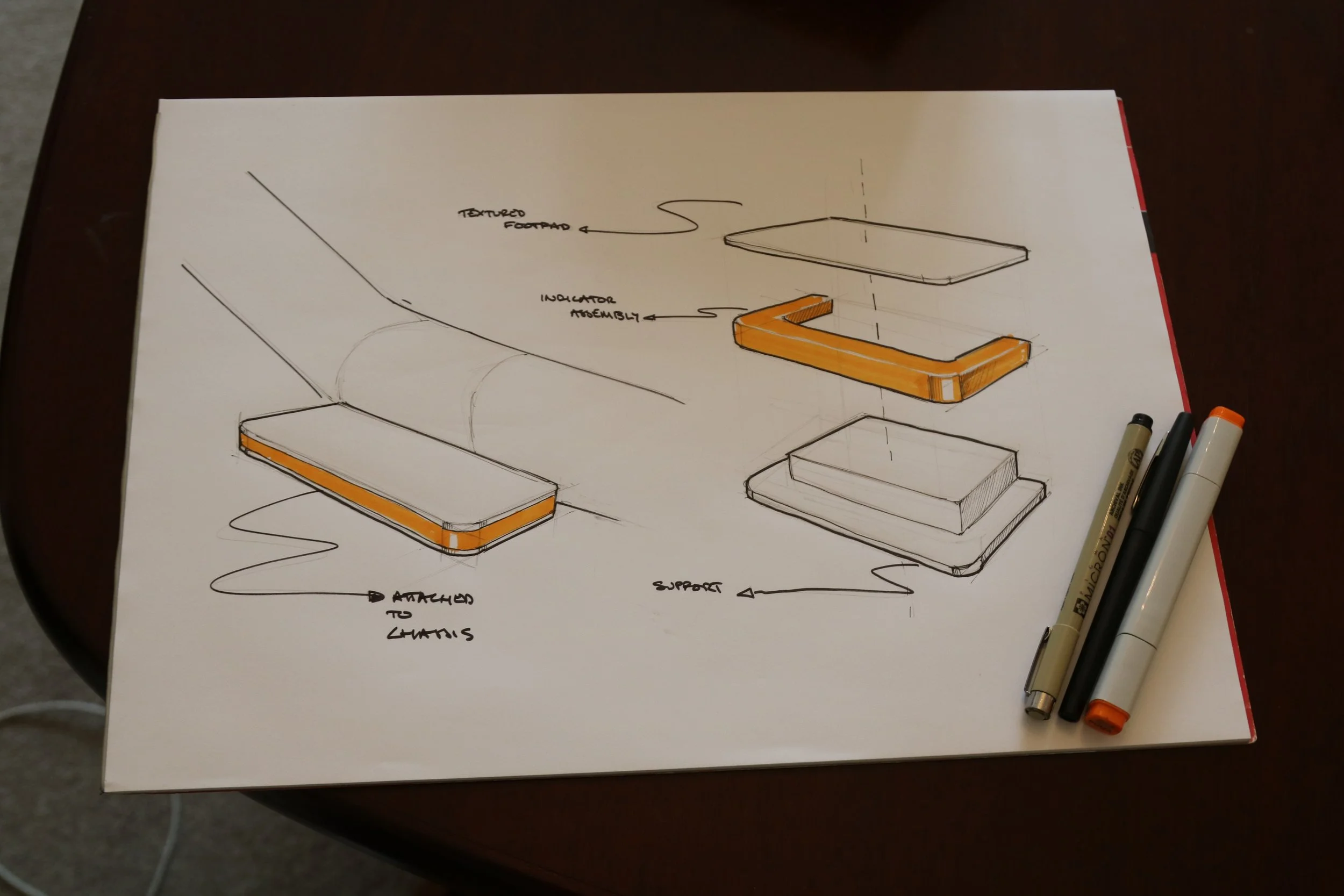

To evaluate solutions, a rigorous design iteration process was followed. Design - Build - Test - Repeat. Fast design loops were achieved using design sketching which were then translated into CAD. The build process included printing of lenses in SLA, control electronics using Arduino which then progressed to machined polycarbonate lenses and full control electronics with design intent LEDs. Real-life use-cases informed the testing requirements (how bright do the indicators have to be to be seen from 100m away in bright sunlight?). Testing was completed at low cost, with no expensive photometric equipment.

-

Engineer and Deliver.

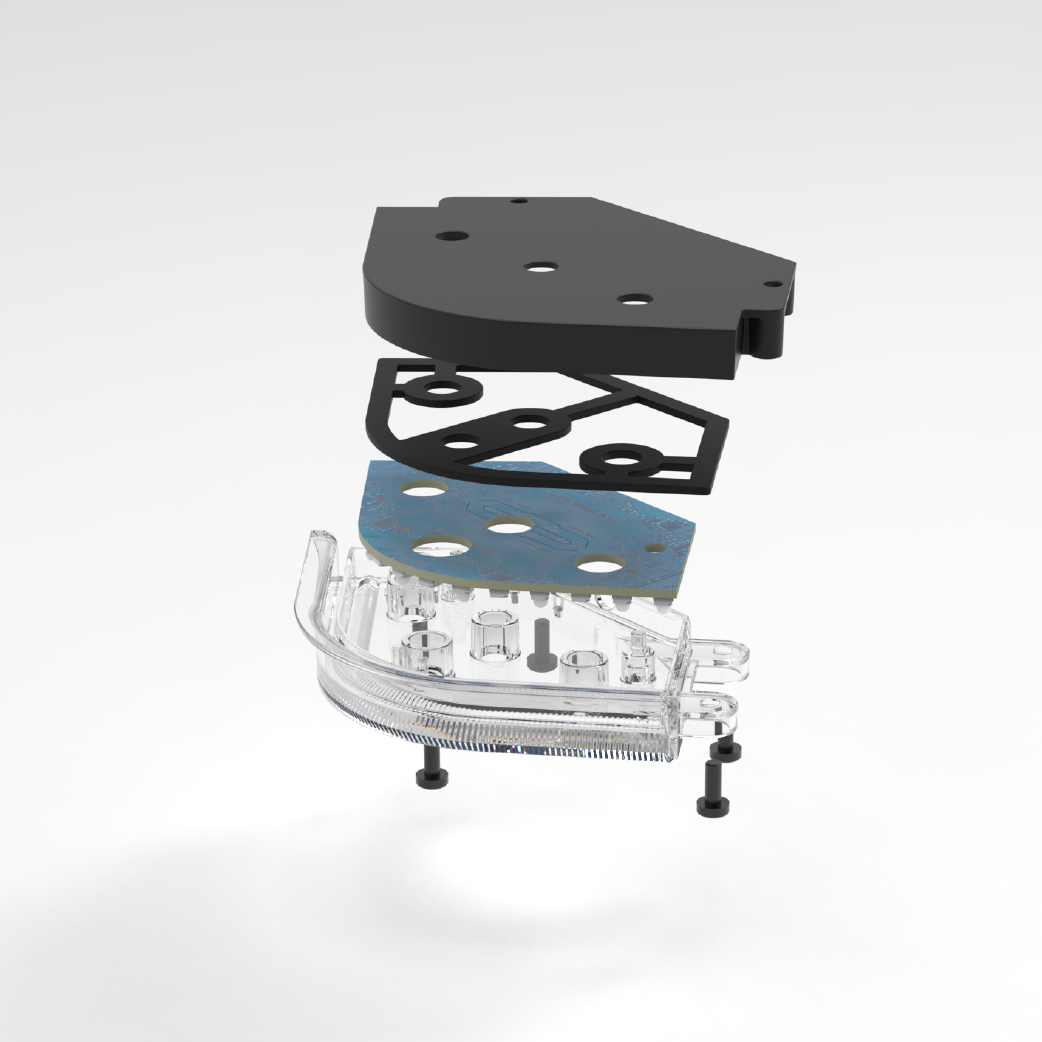

Once the desired behaviour for the indicators was defined—a LED array with a flowing pattern inspired by premium automotive designs, seamlessly integrated into the footplates—the engineering process kicked off. Robustness was key. Given that the indicator assembly carries a load, meticulous design and testing were essential to ensure durability across thousands of journeys.

Anticipating wet environments the indicator assembly was designed to IP67 standards, guaranteeing water and dust resistance. Ultrasonic welding played a pivotal role in achieving this protective seal.

Having addressed these critical aspects, the design for efficient manufacturing and seamless assembly (DFM & DFA) were tackled. This was completed by collaborating with a contract manufacturer, optimizing the production process.